Processes

Aluminium – Industry Heavyweights

Whether you say “aluminium” or “aluminium,” if you smelt, melt, cast, extrude, forge, draw, weld or just heat this lightweight metal, your capital equipment supplier should be the industry’s heavyweights. The Inductotherm Group companies are clearly the most reputable around the world. They design, build, and service today’s most technologically advanced equipment from their facilities spanning the globe. Their products are used in a broad spectrum of industry applications and range from the world’s largest tilting holding furnaces to highly automated induction welding systems for tubing.

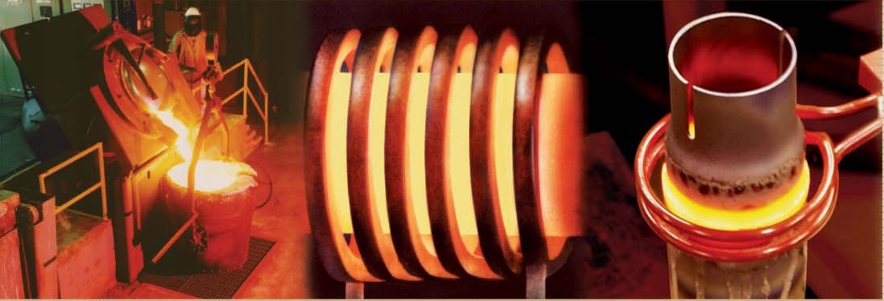

Copper – Inductotherm Group companies take copper processing out of the Bronze Age

Before the dawn of recorded history, man discovered he could make useful tools from copper and its alloys. Today, the metal that was first made into simple axes and arrowheads is the essential ingredient in products ranging from water systems and church bells to electrical transmission networks and computer chips.

And customers of Inductotherm Group companies are involved in producing virtually every one of them. Our customers use our thermal processing systems to melt, cast, form, atomize, roll, forge, extrude, draw, solder, braze, weld, groove, cut, bond and coat copper and its alloys.

Inductotherm Group companies also are significant users of high quality copper products. We use millions of kilograms of copper tubing, bus bars, wires and cables along with copper and brass valves, pipes and electronic components to build power supplies, induction coils, water pumping systems and other equipment for our customers.

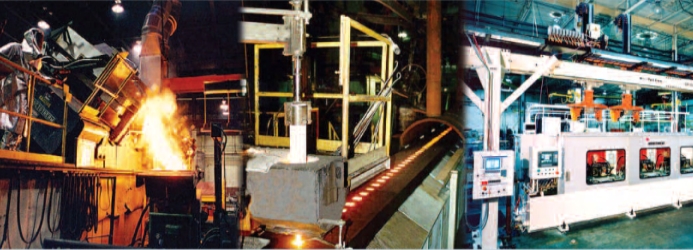

Iron – The Worlds Leading Manufacturers Use Iron Castings Made in Inductotherm Equipped Foundries

The leading manufacturer of agricultural machinery, the world’s largest producer of ductile iron pipe and the best known builder of cast iron bathtubs are just a few examples of the worldwide industry leading companies who rely on iron melting, holding, pouring or heating systems built by lnductotherm Group companies. In fact, walk into an induction iron foundry anywhere in the world and you are most likely to find that its melt shop is equipped with lnductotherm furnaces and power supplies. You also are likely to find lnductotherm automated material charging systems and automatic pouring systems.

When an automotive casting can just as easily come from China, Brazil, Spain or the United States, it is often the quality, productivity and efficiencies provided by lnductotherm systems that give foundries the competitive edge needed to meet the challenges of the international castings market.

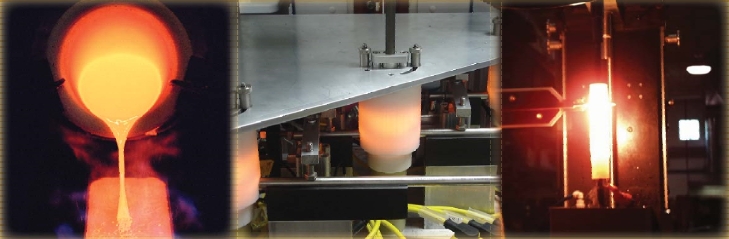

Precious Metals: Intrinsic Beauty & Practical, Everyday Applications

Long before man began using copper and bronze to make simple tools, he was creating beautifuI and intricate objects of gold. Gold was man’s first metal and for all of recorded history, gold, silver and, more recently, platinum were highly valued both for their intrinsic beauty and as an almost universal medium of exchange.

Of course, precious metals continue to be used throughout the world in making beautiful objects and in minting bullion coins. Today, however, precious metals offer far more than glitter. Gold, silver and platinum group metals are performing useful and specialized functions in chemical processes, electronics manufacturing, aerospace and automotive systems, construction, and in dental care and medicine.

Whether precious metals are being used to make stunning jewellery or more commonplace products, it is likely they have been smelted, refined, melted and/or heated with equipment manufactured by lnductotherm Group companies..

Steel’s Productivity Revolution

Technological innovation has changed the steel industry in fundamental ways. Modern integrated mills and mini-mills now produce steel far more efficiently, economically and with less impact on the environment than was possible with the steelmaking technologies in use in the past. Steel product manufacturers also are benefiting from new technologies that enhance productivity and quality.

lnductotherm Group companies are playing a key role in the steel industry’s productivity revolution by building technologically advanced production systems for steelmakers and steel product manufacturers worldwide. These systems include:

- Innovative direct reduced iron (DRI) production furnaces

- Modern induction furnaces for producing silicon iron and steel from sponge iron and/or ferrous scrap

- Vacuum induction melting furnaces (VIM) for special steel alloy production

- Vacuum and controlled atmosphere remelting furnaces for special steels

- Induction Vacuum Ladle (IVL) for alloying and degassing

- Energy efficient reheating furnaces for semi-finished products

- In-line strip annealing, coating and drying systems

- Induction tin-reflow systems

- Gas and induction heating systems for forging

- Heat treating systems

- Heat and quench, annealing and welding systems for pipe, tube and wire manufacturing

- Annealing, heating and welding systems for pipe, tube and wire manufacturing

- Induction furnaces for steel casting production