Bright Annealing Wire Line

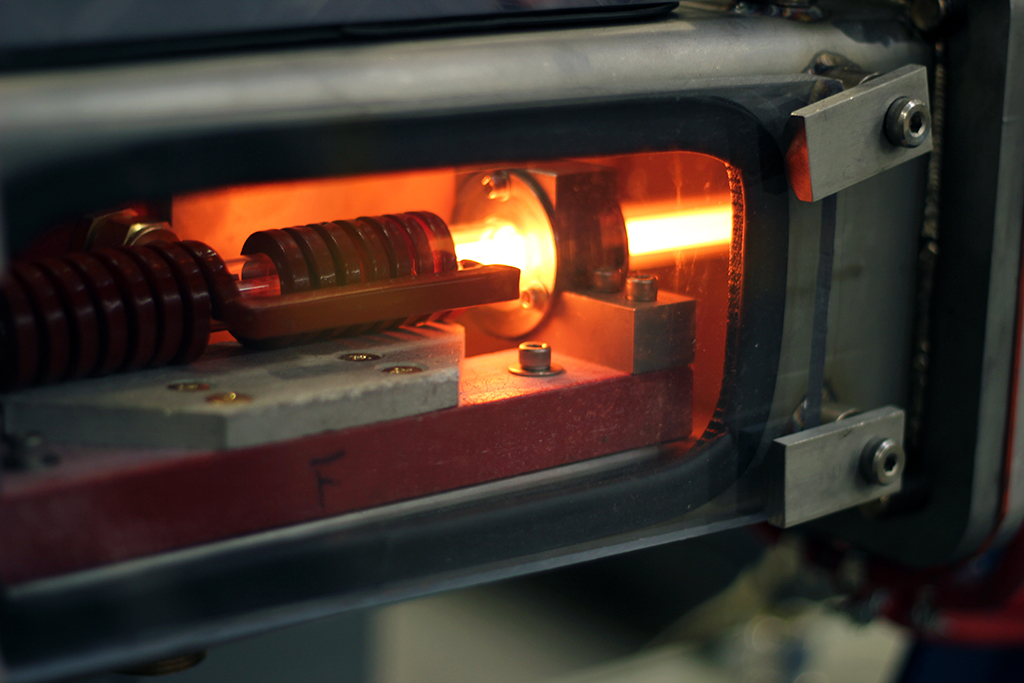

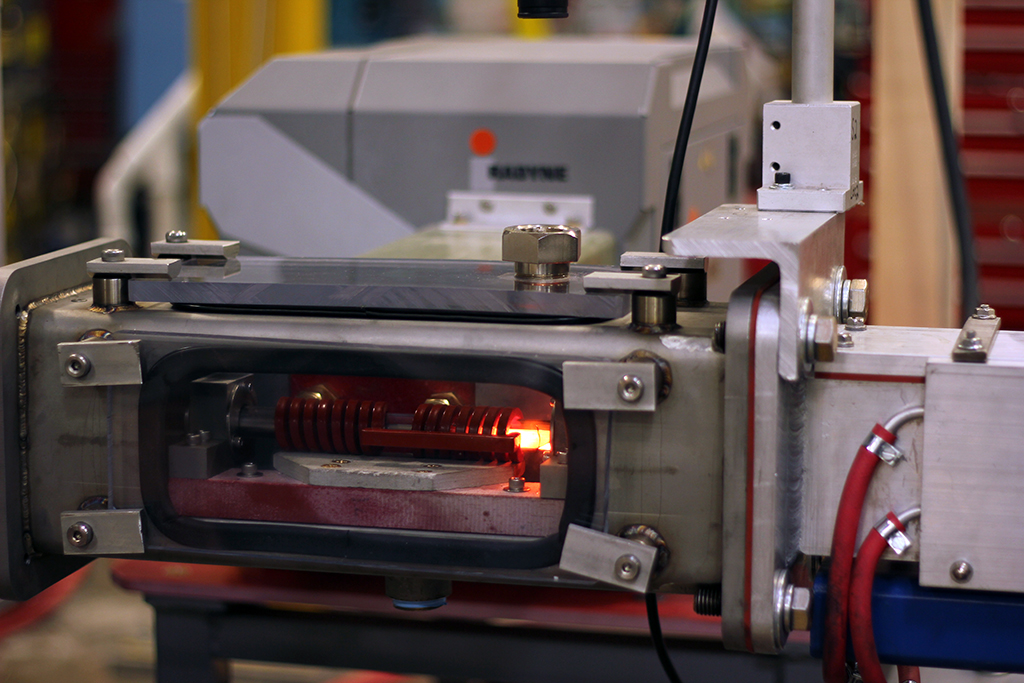

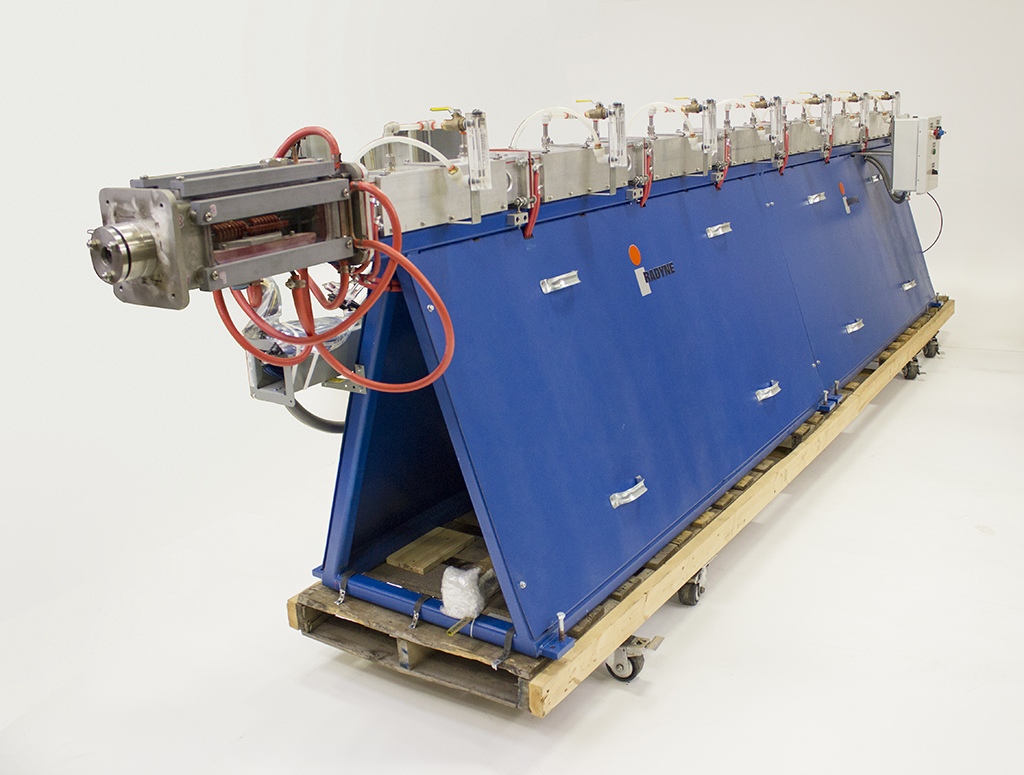

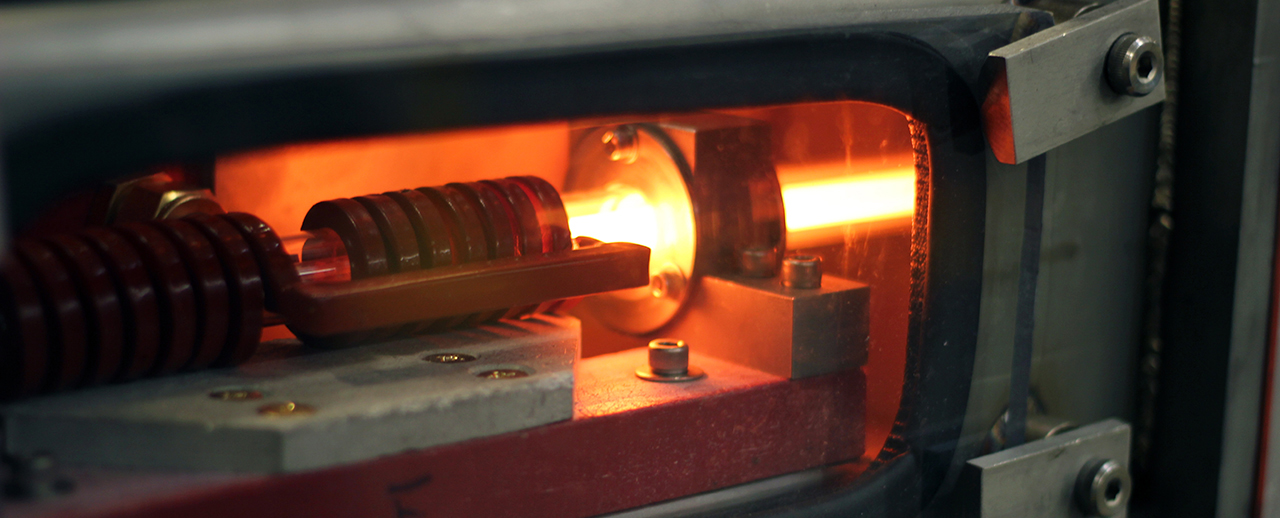

Radyne’s Bright Annealing Systems fit directly in-line with today’s high speed drawing and rolling lines, making them the preferred choice for lean, agile manufacturing.

Features

Utilizing a modular and expandable design, Radyne Annealing Systems meet virtually any line speed, product dimension, or material- supporting oxygen-free copper, brass, titanium, stainless steel, nickel, and more.

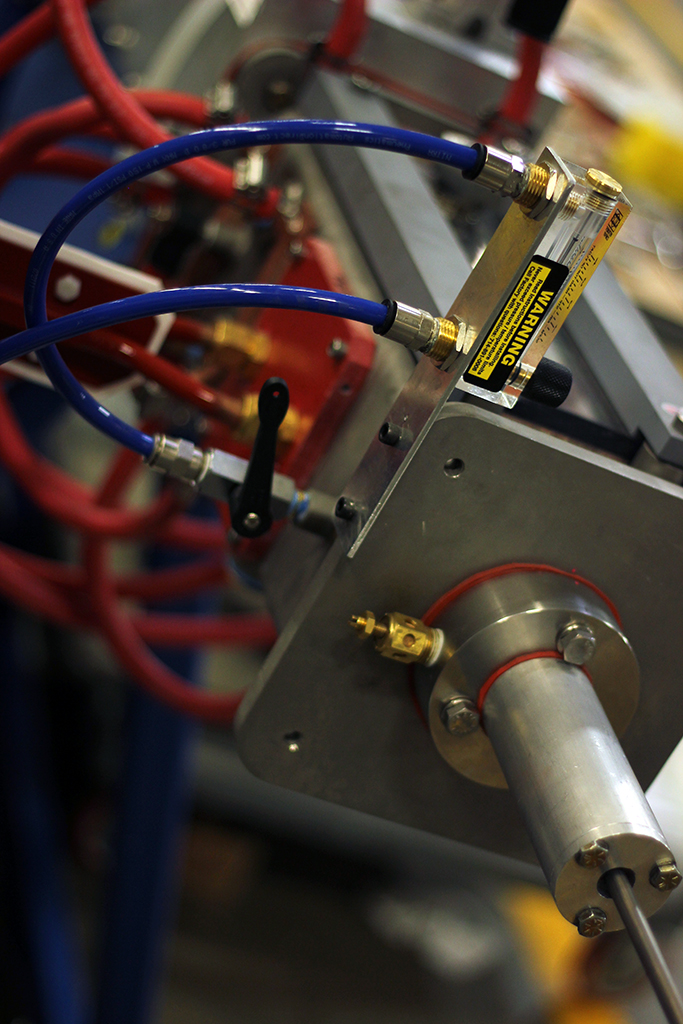

The Bright Annealing Wire System can either be placed standalone or in-line with surface reduction equipment to create a total in-line process. Innovative design allows for easy changeover from product to product, and each system is equipped with automatic power control and precision temperature control through recipe parameters.

- Designed for ease of operation and maintenance

- Automatic speed sensor controls power proportionate to line speed

- Recipe storage and retrieval

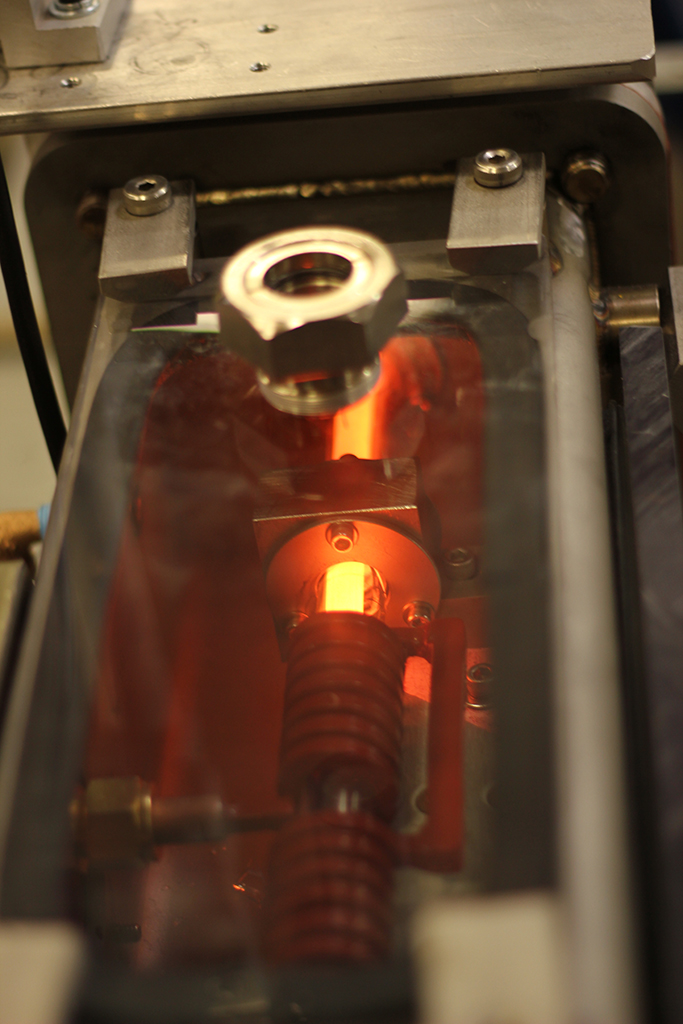

- Integrated temperature sensing

- High wear ceramic tube guides

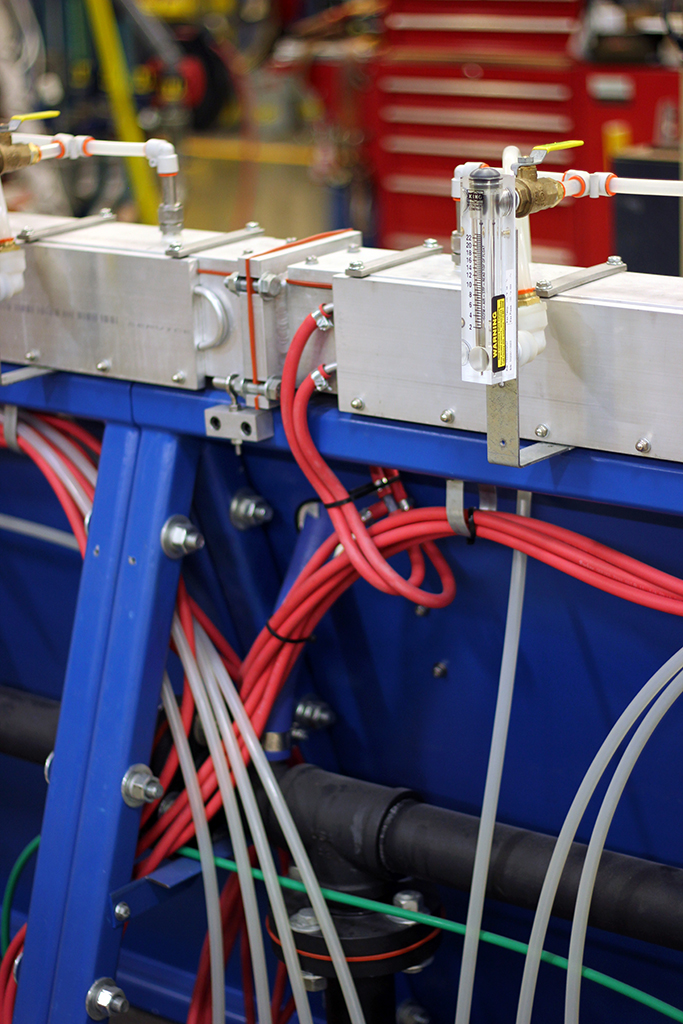

- Integrated pumping system

- Solid state inverters, operating in both medium and high frequencies

Quench Details:

- Optional inert gas quench available

- Optional gas recycling

- Optional gas manufacturing and mixing systems

- Contained Atmospheres – Nitrogen, Nitrogen with up to 4% Hydrogen, Helium, Argon, Argon with Hydrogen

- Water Quench – leaves micron level oxidation, acceptable for inter-process annealing

- Gas Impingement Quench – Finished, high quality surface

Tech Specs

| Bright Annealing Wire System | ||

| Size | 2 mm – 16 mm wire | |

| Speed | up 100 ft/min [30 m/min] | |