FlexScan Scanners

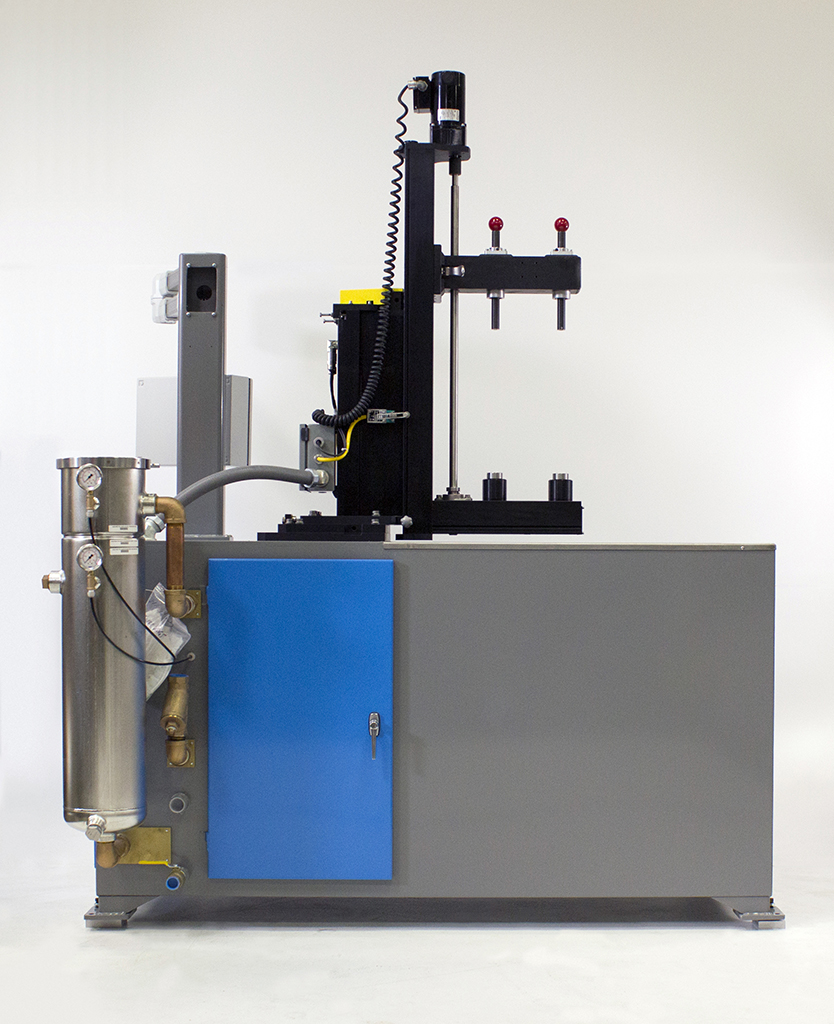

Flexscan™ induction scanners break new ground by delivering the most affordable scanner in the marketplace.

Initially designed for heat-treating processes for both in-place or scan, the Radyne FlexScan™ scanner can be adapted for different heat-treating and brazing applications. FlexScan™ Scanners and Pop-Ups are economical, modular, ideal for small parts, and are easily configurable for different part types.

Features

Due to its modular design, the base Flexcan™ scanning system may be easily adapted to suit different induction heating processes including, but not limited to, heat treating, brazing and soldering, shrink fitting, and even heat staking.

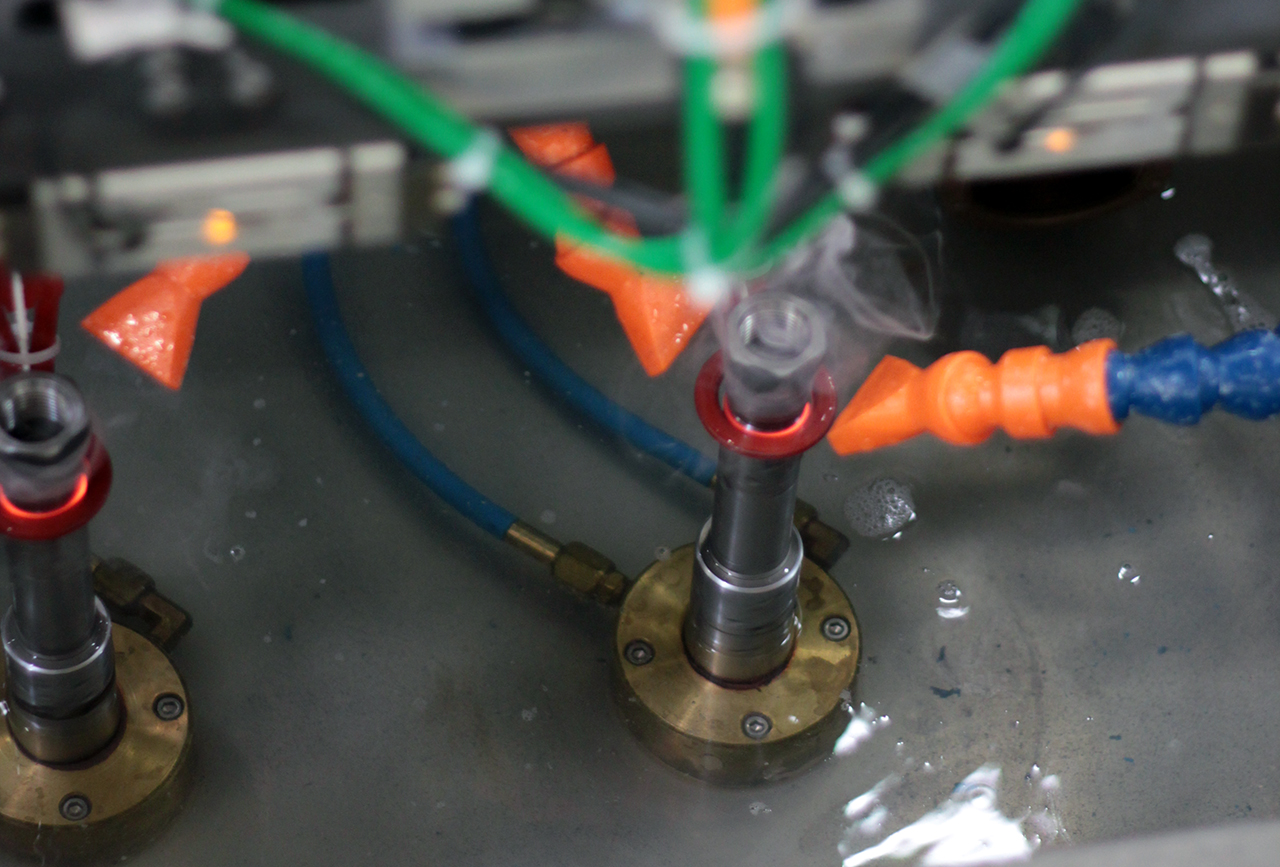

The FlexScan™ scanner incorporates only non-ferrous materials in the built-in modular quench and water recirculating systems.

The operators interface features a full colour HMI with embedded controls. The modular design allows for the system to be easily adapted into various production arrangements, and provides for simplicity in diagnostics and maintenance.

FlexScan™ scanners offers several scanner personalities:

- In place

- Fixed pop

- Scan pop

- Single feed multi-zone

- Multi-feed multi-zone

Features:

- Dual or single spindle models

- Built-in quench tank

- Recipe call on demand

- Virtually limitless control possibilities for the most challenging induction heating specifications

- Optional QAS 2000 Monitoring and Alerting System for process monitoring and trace-ability for each part processed

- Compact and portable flexible lift and rotate system

Tech Specs

|

|

||||

| FlexScan™ 12 | FlexScan™ 28 | FlexScan™ 36 | |||

|---|---|---|---|---|---|

| Scan Length | 12 in [30 cm] | 28 in [71 cm] | 36 in [91 cm] | ||

| Scan Speed | 3.5 in per second [88 mm per second] |

3.5 in per second [88 mm per second] |

3 in per second [76 mm per second] |

||

| Rotation Speed | 0 – 185 RPM | 0 – 400 RPM | 0-30 RPM | ||

| Part Weight | 75 lbs per spindle [34 kg per spindle] |

75 lbs per spindle [34 kg per spindle] |

2,500 lbs [1133 kg] |

||

| Part Diameter | 6 in (dual spindle) [152 mm (dual spindle)] |

6 in (dual spindle) [152 mm (dual spindle)] |

60 in [152 cm] |

||

| Spindles | Single or dual | Single or dual | Single | ||

| Quench | 20 GPM 35 Gal [75 LPM 132 L] |

50 GPM 200 Gal [189 LPM 757 L] 100 GPM 300 Gal [378 LPM 1135 L] |

300 GPM 1300 gal [1135 LPM 4921 L] |

||

| Operator interface | Color HMI & embedded controls | ||||