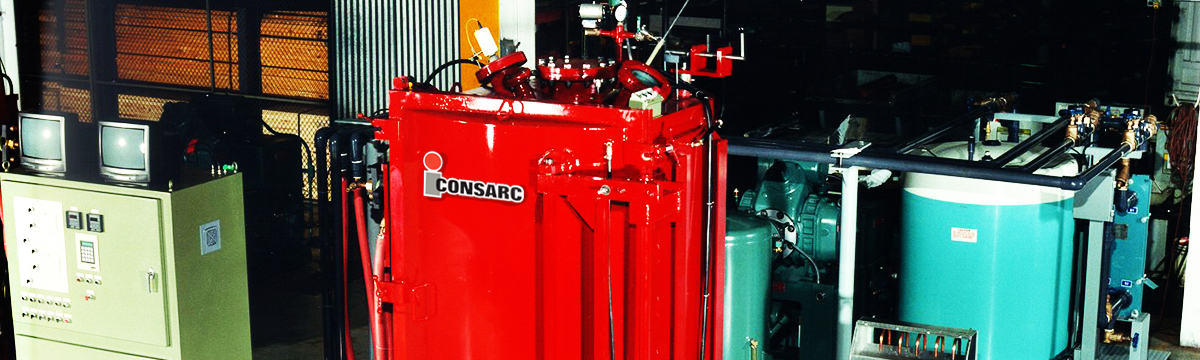

Single Chamber Induction Skull Melting Furnace

Consarc offers Induction Skull Melting (ISM) furnaces which is a method of melting metals in a segmented water-cooled copper vessel while under vacuum or controlled atmosphere using an induction coil. Consarc’s single chamber design is for low volume prototype castings and R&D work. Consarc ISM furnaces provide superior chemical and thermal homogenaity when compared to more traditional methods of melting reactive materials such as arc skull casting.

Features

• Excellent for R&D and Prototype Castings

• Low Overhead Clearance

• Small Footprint

• Flexible

• Upgradeable to a tandem unit at a later time

Tech Specs

Capacities: 5kg – 100kg+

Vacuum Levels: up to 1×10-5 torr

Centrifugal casting up to 400 RPM

Copper Crucible from a single forged piece of material

CCTV System for viewing melt remotely

Remote controls for safe operation

Accessories

• Cup charger

• Centrifugal casting

• Bridge breaker

• Immersion Thermocouple

• Pyrometer

• High Vacuum Pumps (Diffusion or Oil Vapor Booster)